GET A QUOTE

Main Menu

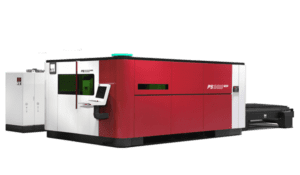

Our Eagle 30kW fiber laser delivers a cut speed 2 to 4 times faster than other lasers. The exclusive eVa high-power cutting head ensures full reliability at such high speeds. The motion system delivers up to 6G’s with a cutting speed of 13,000 inches/minute. That’s faster than you eye can track. Our Eagle Laser is ready for 24/7 operation in our shop to meet your cutting needs.

EAGLE FiberLaser Capacities

.030″ to 3/4″ 5052 and 6061 Aluminum

.030″ to 1″ Stainless Steel

.030″ to 1″ Carbon Steel

Tolerances +/- .003″

5′ x 10′ Table

Our Eagle 20kW fiber laser delivers a cut speed 2 to 4 times faster than other lasers. The exclusive eVa high-power cutting head ensures full reliability at such high speeds. The motion system delivers up to 6G’s with a cutting speed of 13,000 inches/minute. That’s faster than you eye can track. Our Eagle Laser is ready for 24/7 operation in our shop to meet your cutting needs.

EAGLE FiberLaser Capacities

.030″ to 3/4″ 5052 and 6061 Aluminum

.030″ to 1″ Stainless Steel

.030″ to 1″ Carbon Steel

Tolerances +/- .003″

6′ x 12′ Table

Laser cutting is both more precise and less energy-consuming than plasma cutting but has a limit on the thickness of the material being cut. Laser Cutting offers complete versatility & high cutting speeds, requires no tool sharpening thus increases profitability.

Laser can provide tolerances as close as +/- 0.003” and are a better choice when needed with no added costs

HK Fiber Laser Capacities

.030″ to 1/2″ 5052 and 6061 Aluminum

.030″ to 1/2″ Stainless Steel

.030″ to 3/4″ Carbon Steel

Tolerances +/- .003″

5′ x 10′ Table

Deburring performs edge rounding and removes sharp edges on both external and internal contours of stainless steel, steel or aluminium parts either cut in laser, shear or punching machine.

Deburring Capacities

edge rounding up to 1100mm

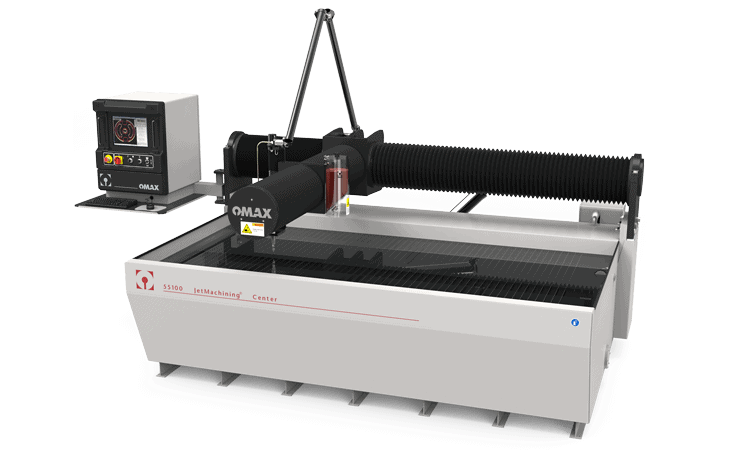

Waterjet cutting is a proven process in precision part production. It is able to make complex flat parts out of most any materials including metal, plastic, glass, ceramics, and composites. Waterjet Cutting offers complete versatility & high cutting speeds, requires no tool sharpening, increases profitability, and is environmentally friendly.

OMAX Water Jets Capacities

Shim stock to 9″ thick materials (all types)

Tolerances +/- .005″ to .050″ depending on thickness and materials.

Tilt-A-Jet to eliminate taper in cut.

5 Machines with tables up to 80″ x 20′

Cutting speed and edge quality are directly related to abrasive waterjet machining. Both refer to the roughness and squareness of the cut edge. In general terms, higher quality means slower cutting speed. The speeds range from Quality 1 (Q1) to Quality 5 (Q5) with Q5 being the best & most accurate edge quality. The cutting speed can be changed depending on the needs of your project to best fit budget/time restraints.

Below are examples of edge qualities Q1 through Q5.

Fast rough cut known as a separation cut.

Medium roughness with less noticeable striations.

Most commonly used edge quality with good results.

High quality finish with minimal striations.

Very high quality finish with no striations.

A press brake is typically narrow and long so that large pieces of sheet metal can be bent by it. A press brake bends sheet metal by lowering a punch onto sheet metal that has been positioned on top of a die.

Accurpress ACCELL E Press Brake

250 ton x 12′ long

Precision state of the art tooling

Positional accuracy of +/-0.0004 inches

Marzee Cutting Services has expanded its cutting capabilities to include two Fiber Laser cutting machines and five Water Jets. We now can service all of your cutting needs in an accurate and timely manner as we have done for the last 23 years.

Check out our sales video

MarZee offers over a decade of expert precision cutting services for aerospace, architecture, entertainment, and environmental design industries.