Precision Strategies for Optimizing Laser Cutting Efficiency in Phoenix

Explore our guide on maximizing efficiency in laser cutting operations, tailored for businesses in Phoenix. From material selection to machine settings, learn expert tips for cost-effective and precise laser cutting solutions near you.

In the realm of precision manufacturing, our guide, “Maximizing Efficiency: Tips for Optimizing Laser Cutting Operations,” serves as a cornerstone for businesses in Phoenix. Laser cutting has evolved into a technology that offers remarkable efficiency and cost-effectiveness, and the quest for perfection is ongoing. To ensure your laser cutting operations in Phoenix are as efficient and cost-effective as possible, consider the following tips and strategies.

Choose the Right Material: The Foundation of Success

The journey to optimal laser cutting begins with selecting the right material. Material choice not only influences cut quality but also impacts efficiency. Various materials have distinct characteristics and requirements, including stainless steel, aluminum, and carbon steel.

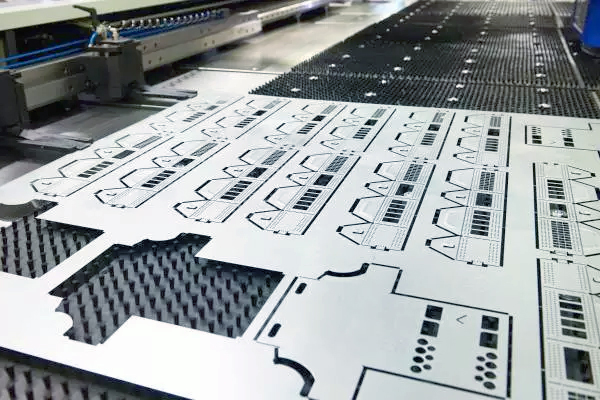

Design with Efficiency in Mind: Precision Matters

Efficient laser cutting starts with precision in design. Nesting parts closely together minimizes material waste, and nesting software optimizes component arrangement on the sheet to reduce scrap. Design parts with minimal piercing points to save time, and utilize bridge cutting techniques to minimize separate piercings.

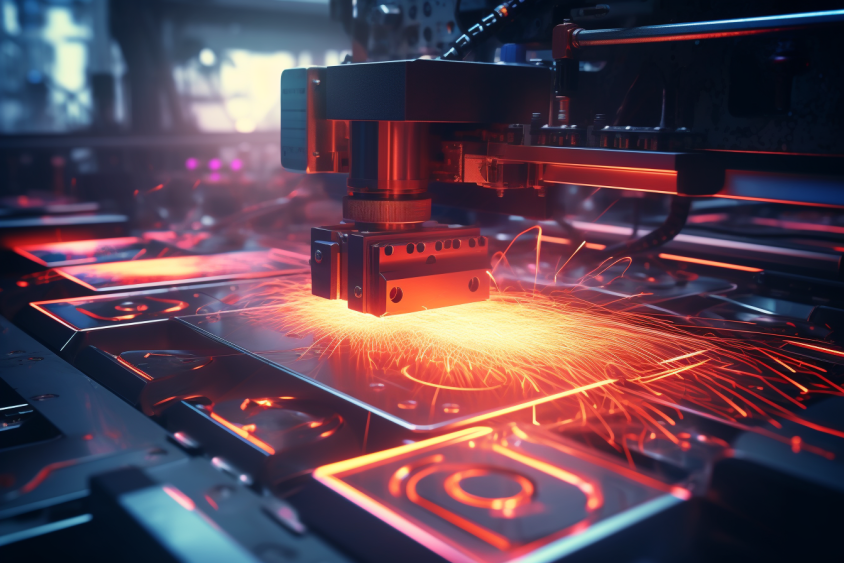

Machine Settings: Fine-Tuning for Perfection

Efficient laser cutting hinges on machine settings. Consider power and speed adjustments based on the material and thickness. The choice of assist gas, whether nitrogen, oxygen, or compressed air, significantly impacts cut quality. Ensuring the correct focus of the laser beam is crucial for precision cuts, and regular inspection and replacement of nozzles maintain cutting quality and efficiency.

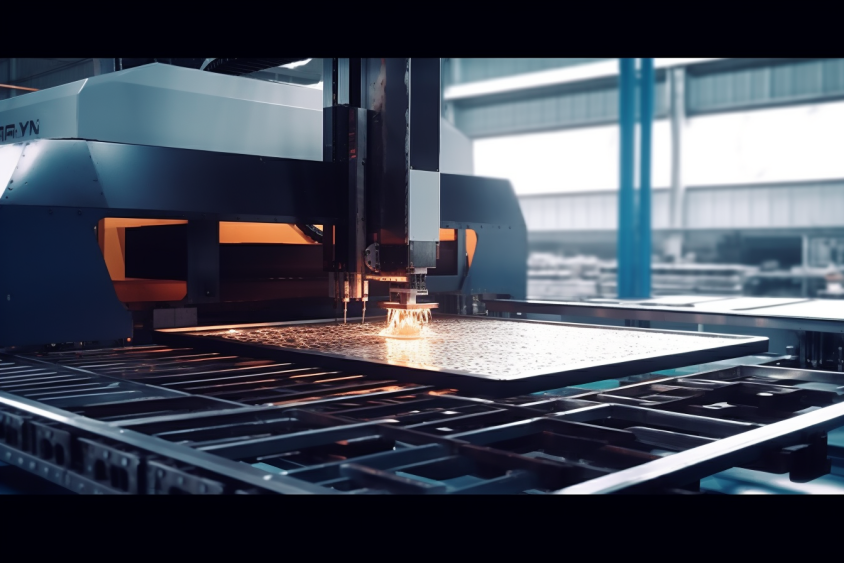

Automation: The Key to Streamlined Operations

Incorporating automation enhances laser cutting efficiency. Modern machines often feature automatic loading and unloading systems, reducing manual labor and allowing for continuous, uninterrupted cutting. Automation streamlines the process, minimizing idle machine time for Phoenix businesses.

Maintenance and Calibration: The Sustaining Force

Regular maintenance and calibration are unsung heroes in efficient laser cutting. A well-maintained machine operates at peak performance, ensuring consistently accurate and clean cuts. Routine checks and preventive maintenance identify issues before they become significant problems.

Unlocking the Full Potential of Laser Cutting in Phoenix

Laser cutting is not just a technology; it’s a craft demanding precision and ongoing optimization. By choosing the right materials, designing efficiently, fine-tuning machine settings, incorporating automation, and maintaining equipment, Phoenix businesses can unlock the full potential of laser cutting. Efficiency and cost-effectiveness become the hallmarks of laser cutting operations, contributing to the bottom line and product quality.

Discover more about our laser cutting capabilities at MarZee Home. Learn about our company’s story in our About Us section. Explore the diverse applications and industries we serve. View examples of our work in our Gallery/Portfolio. Ready to optimize your laser cutting operations? Get a quote now.